History and establishment

Elektro Sochor spol. s r. o.-ŠMERAL Group is a subsidiary of ŠMERAL Brno, a.s., which bacame famous by production of castings, later production of Kaplan turbines and since 1925 production of forming machines.

Our company independent history dates back from September 30, 1994.

Company Elektro Sochor spol. s r.o. - ŠMERAL Group is registered in the Commercial Register kept by the Regional Court in Brno, Section C, File 16727.

Production program

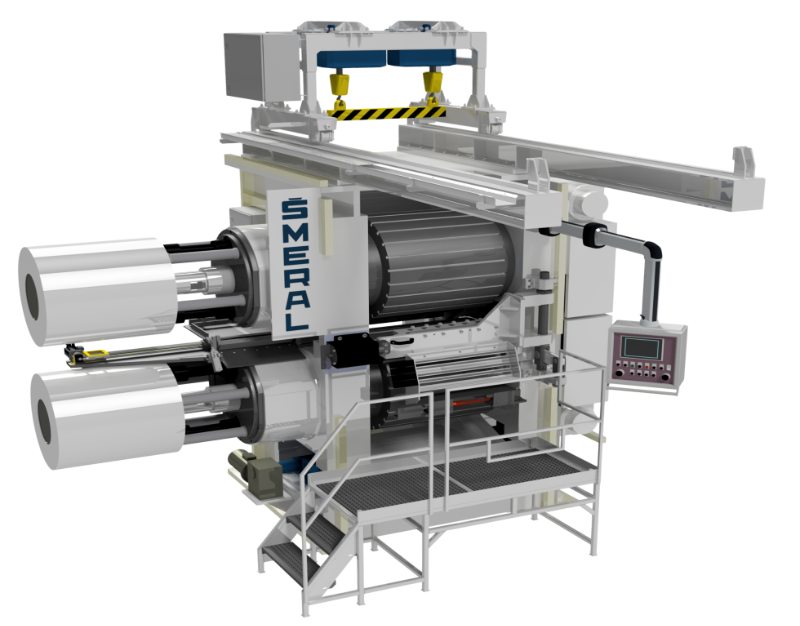

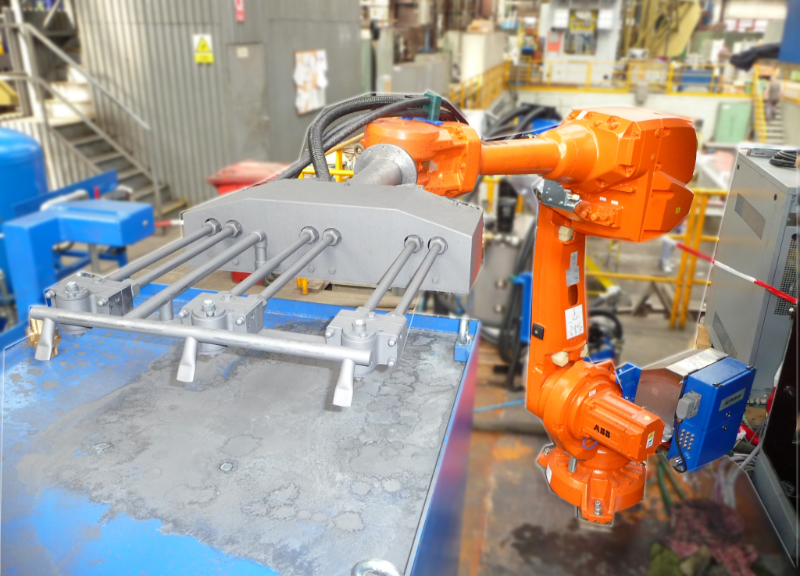

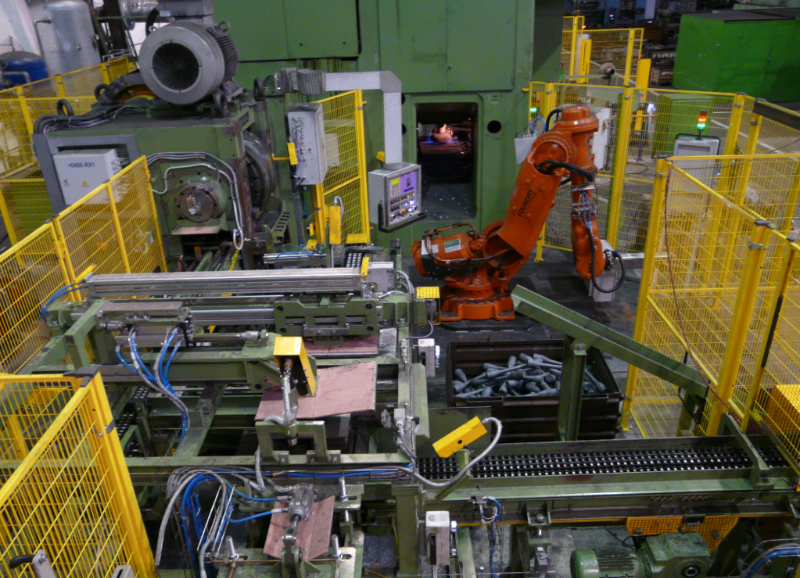

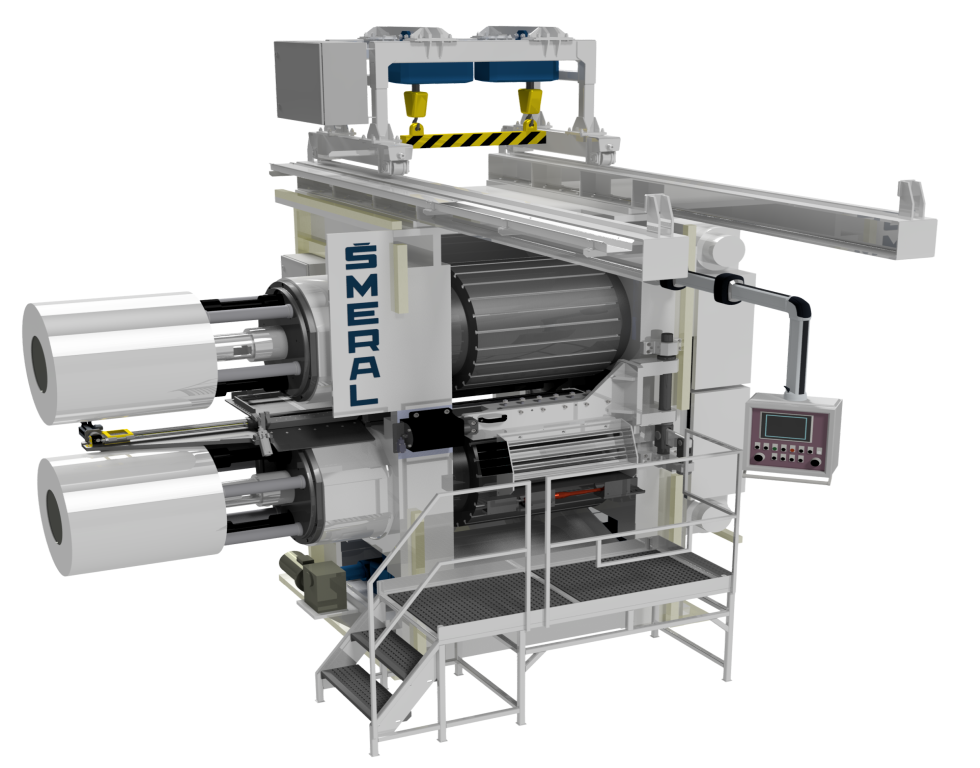

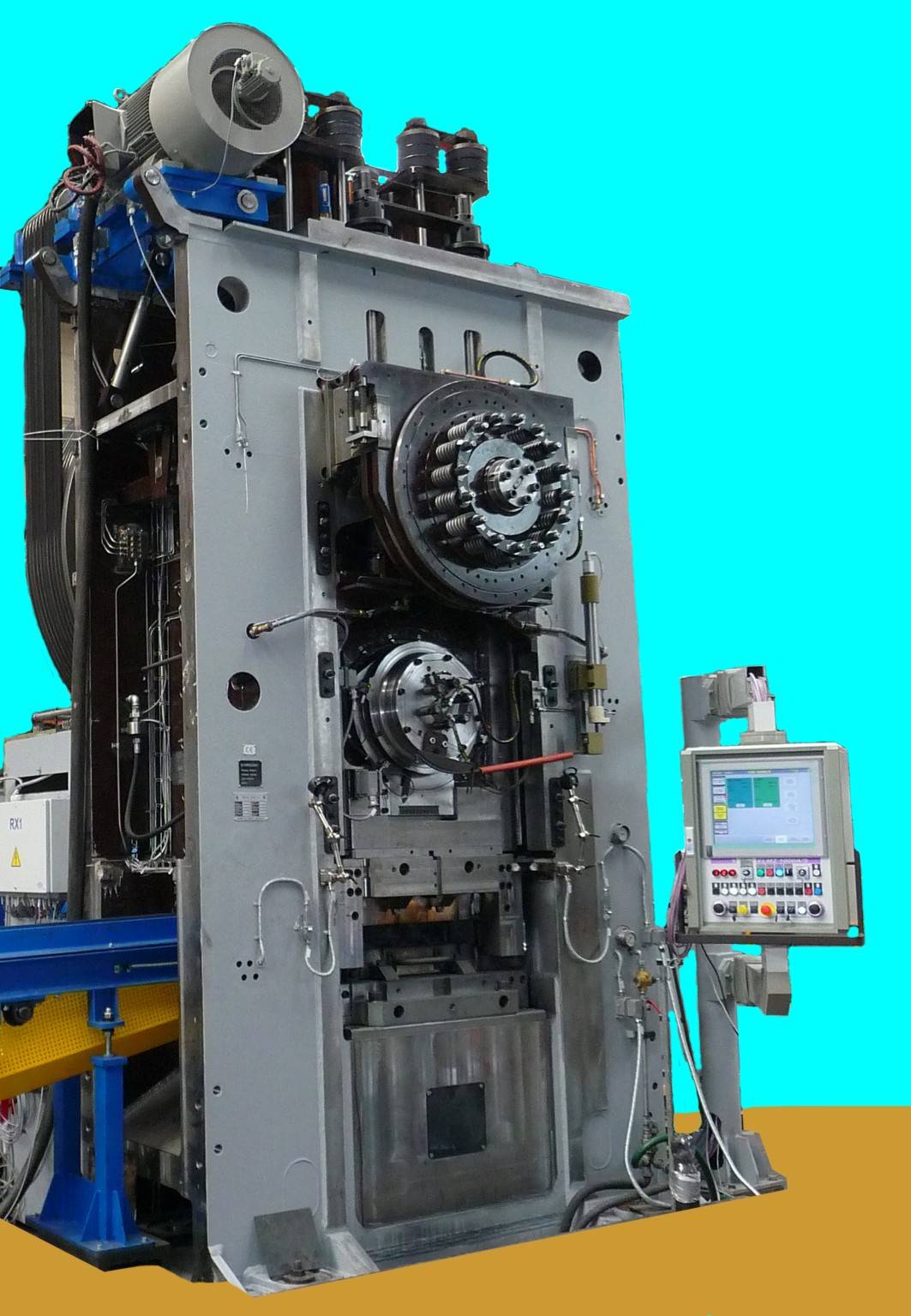

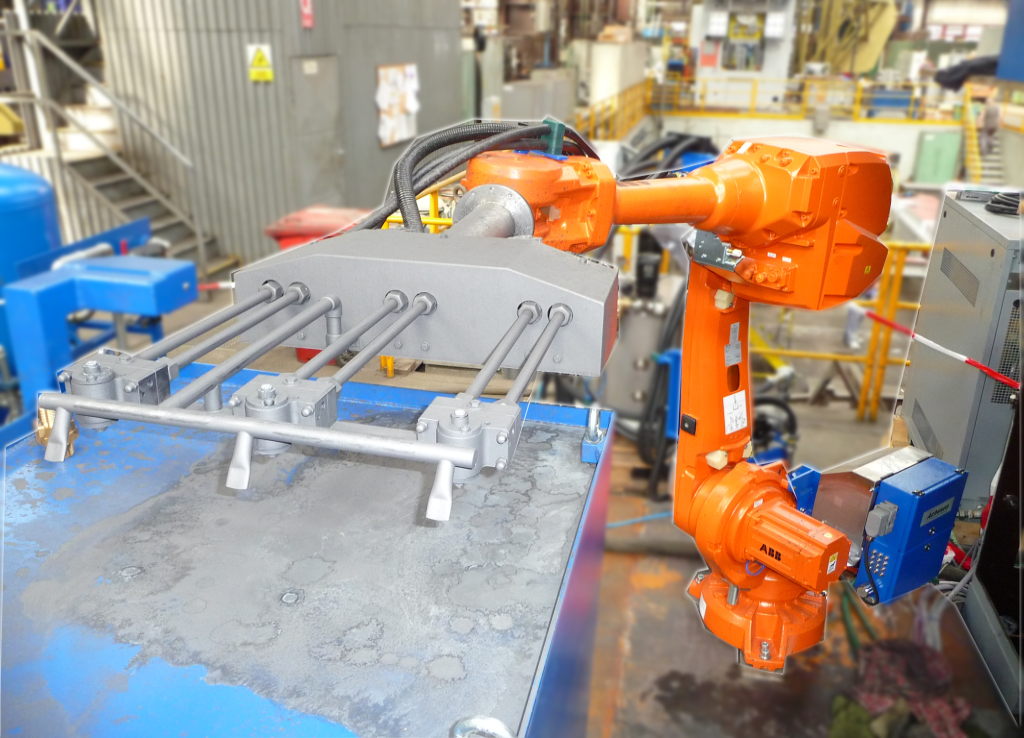

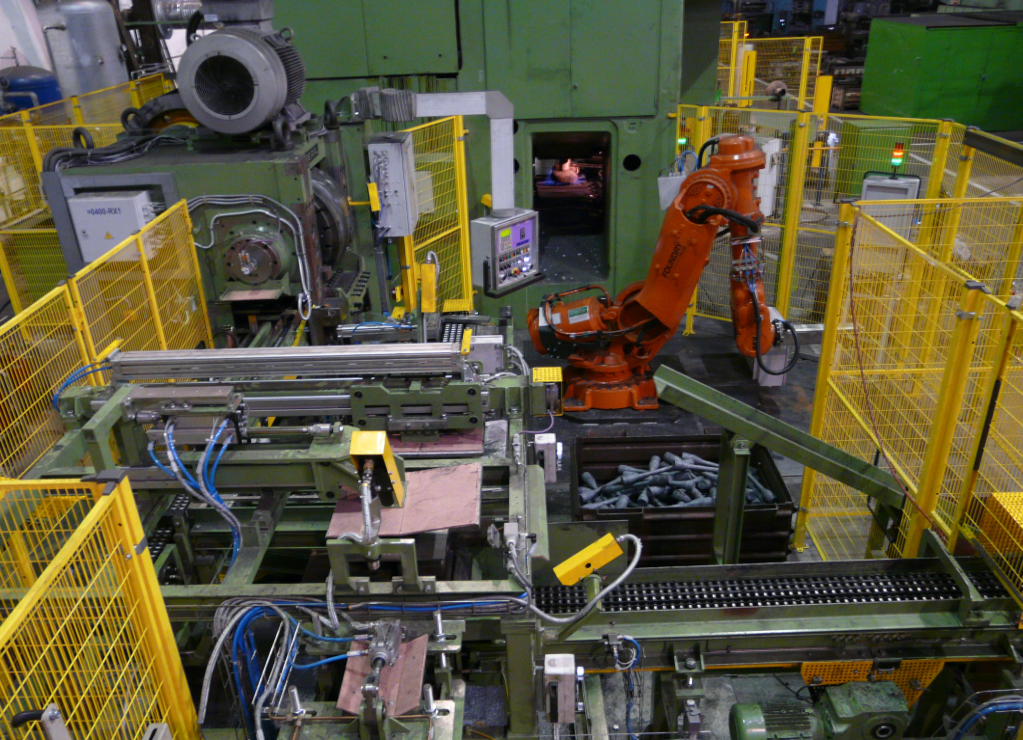

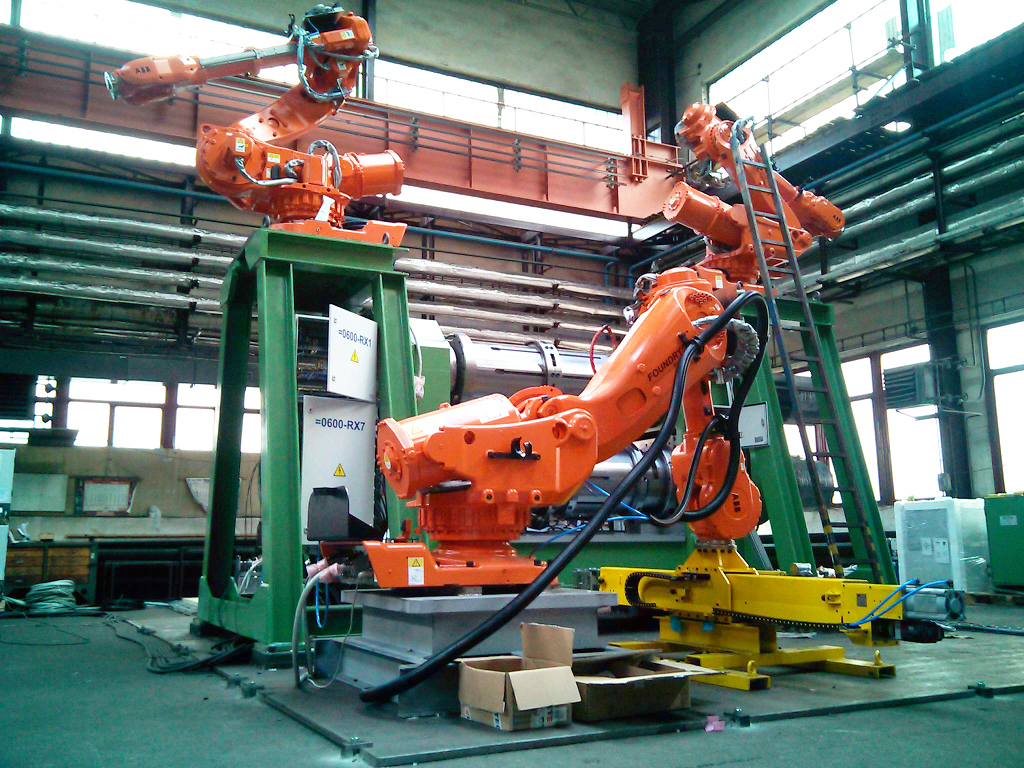

Complex supplier activities in the field of manual, semi-automatic and automatic forming lines and robotized workplaces

Design and production of atypical machine equipment included in the line

Design and production of mechanized and automated nodes for forging shops and pressing shops

General overhauls of forming machines according to Statutory Order No. 378/2001 Coll.

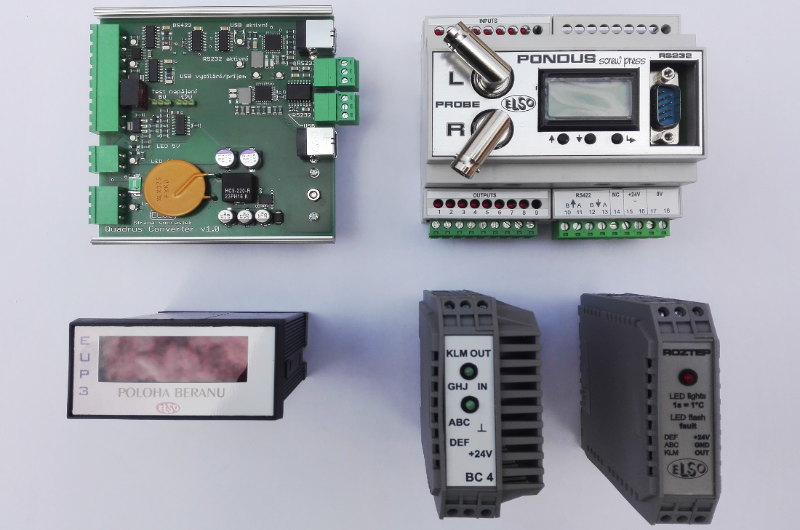

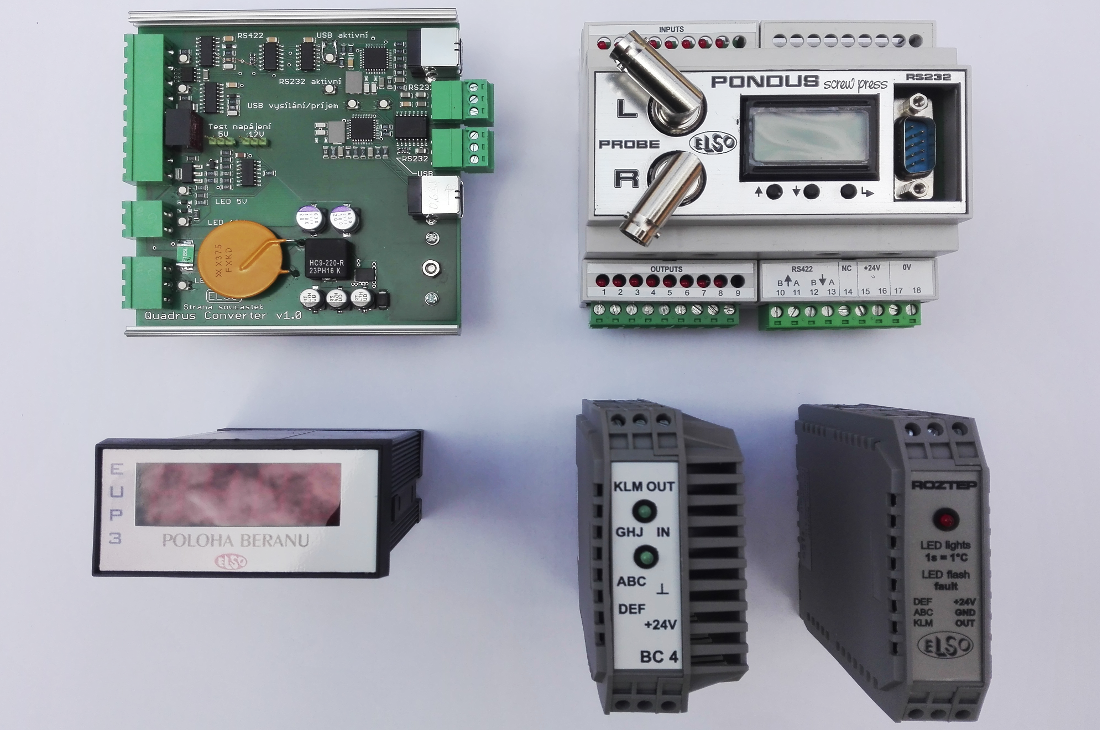

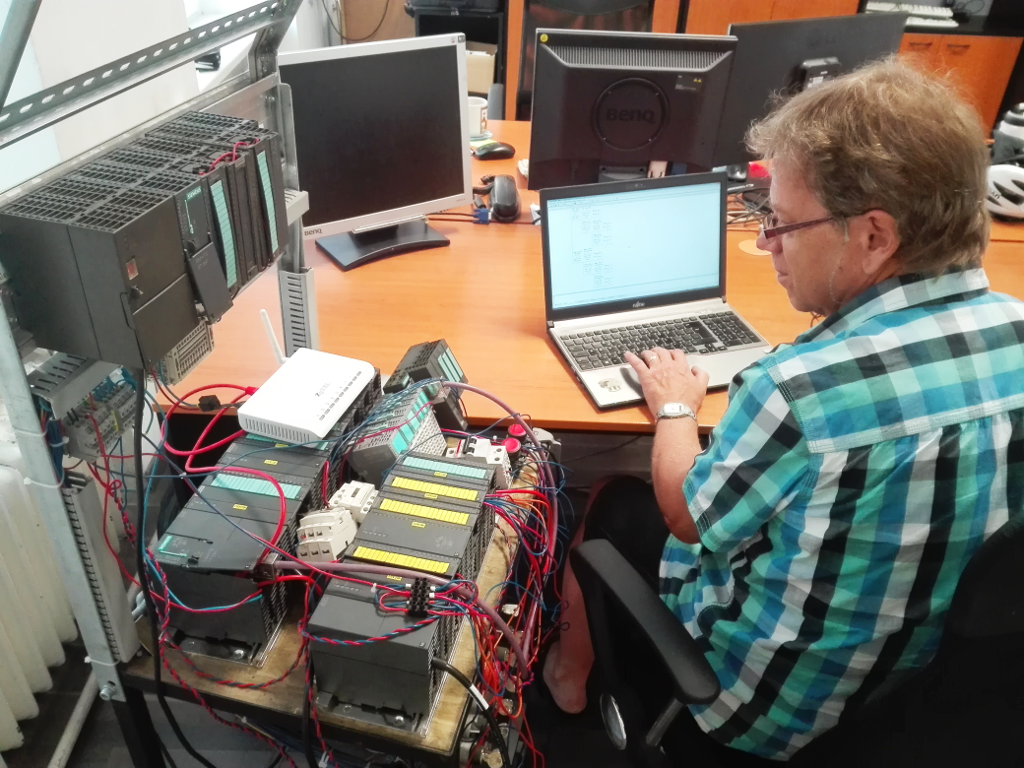

Electrical and electronic equipment

Electrical maintenance and repairs